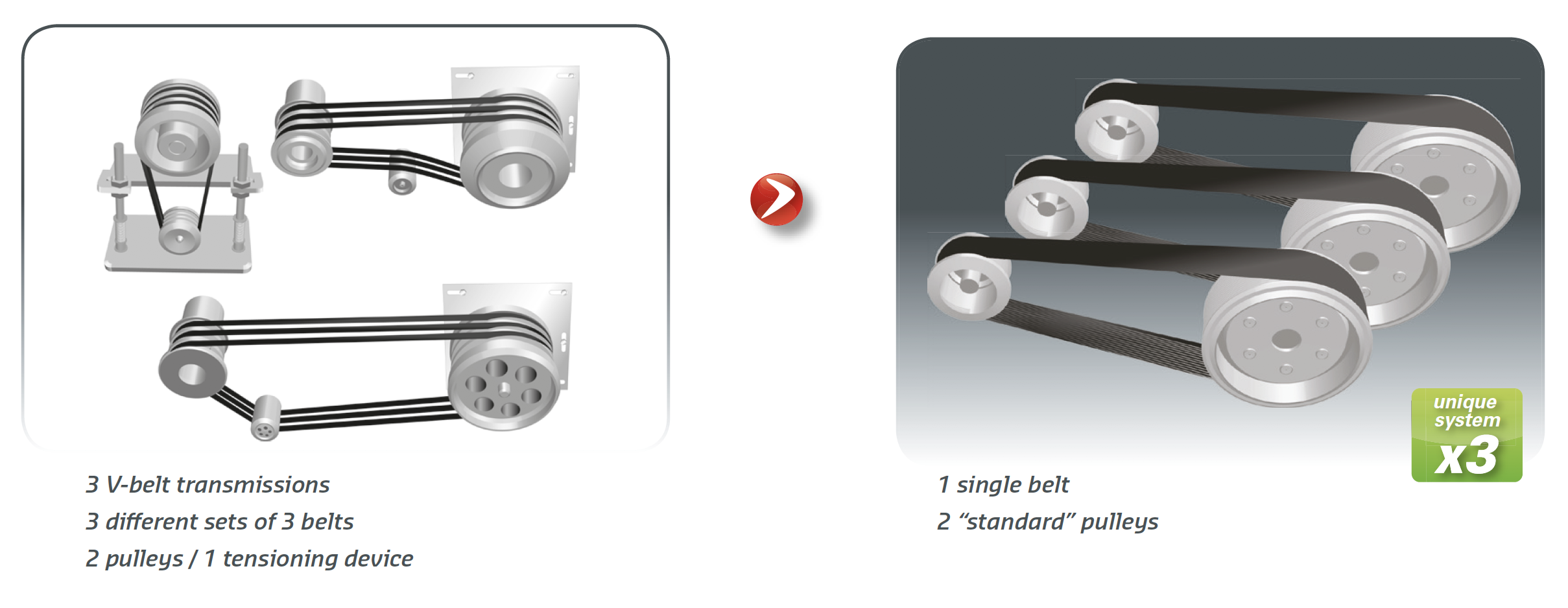

V-belt can be converted

to Hutchinson ribbed belt.

WHY SWITCH FROM V BELT TRANSMISSION

TO RIBBED BELT TRANSMISSION ?

We offer you to convert Vbelt transmission to ribbed belt transmission.

Here are the main advantages of this conversion:

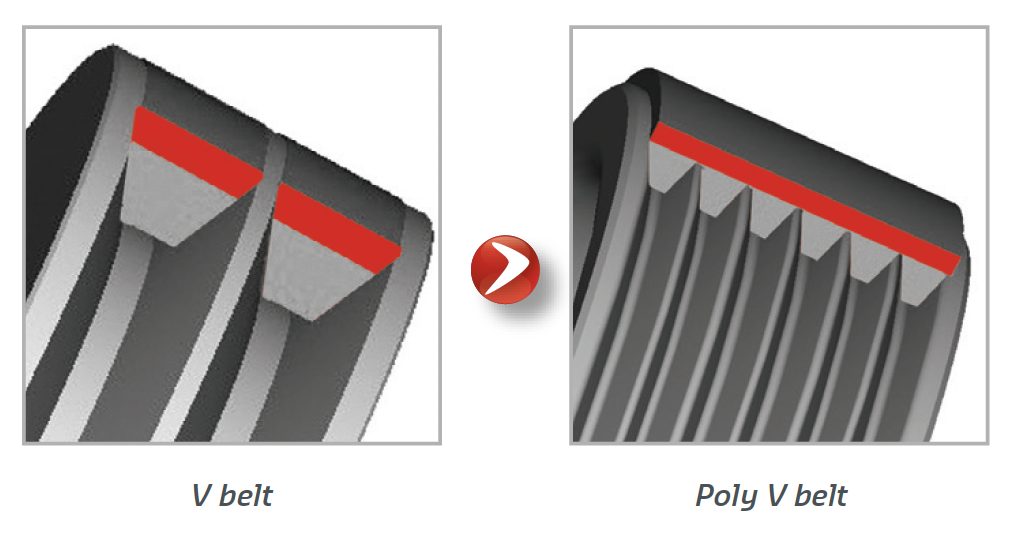

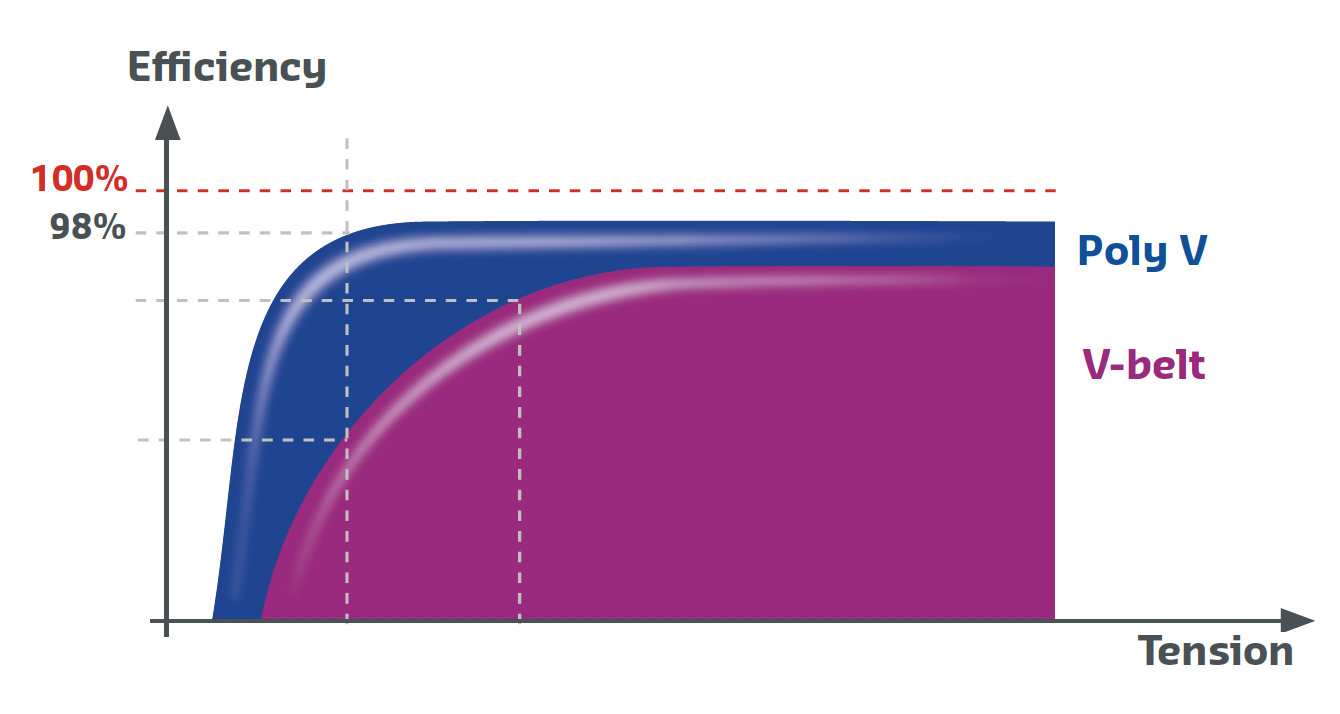

THE EFFICIENCY OF THE TRANSMISSION

Higher power transmission by continuous and uniform cord.

A larger contact surface than V belts.

Technical studies have revealed that at the same tension and with the same geometry the Poly V compared to V-Belt has an upper yield : it is situated on average around 98 %, a fact that reduces electricity consumption and the size of the motor.

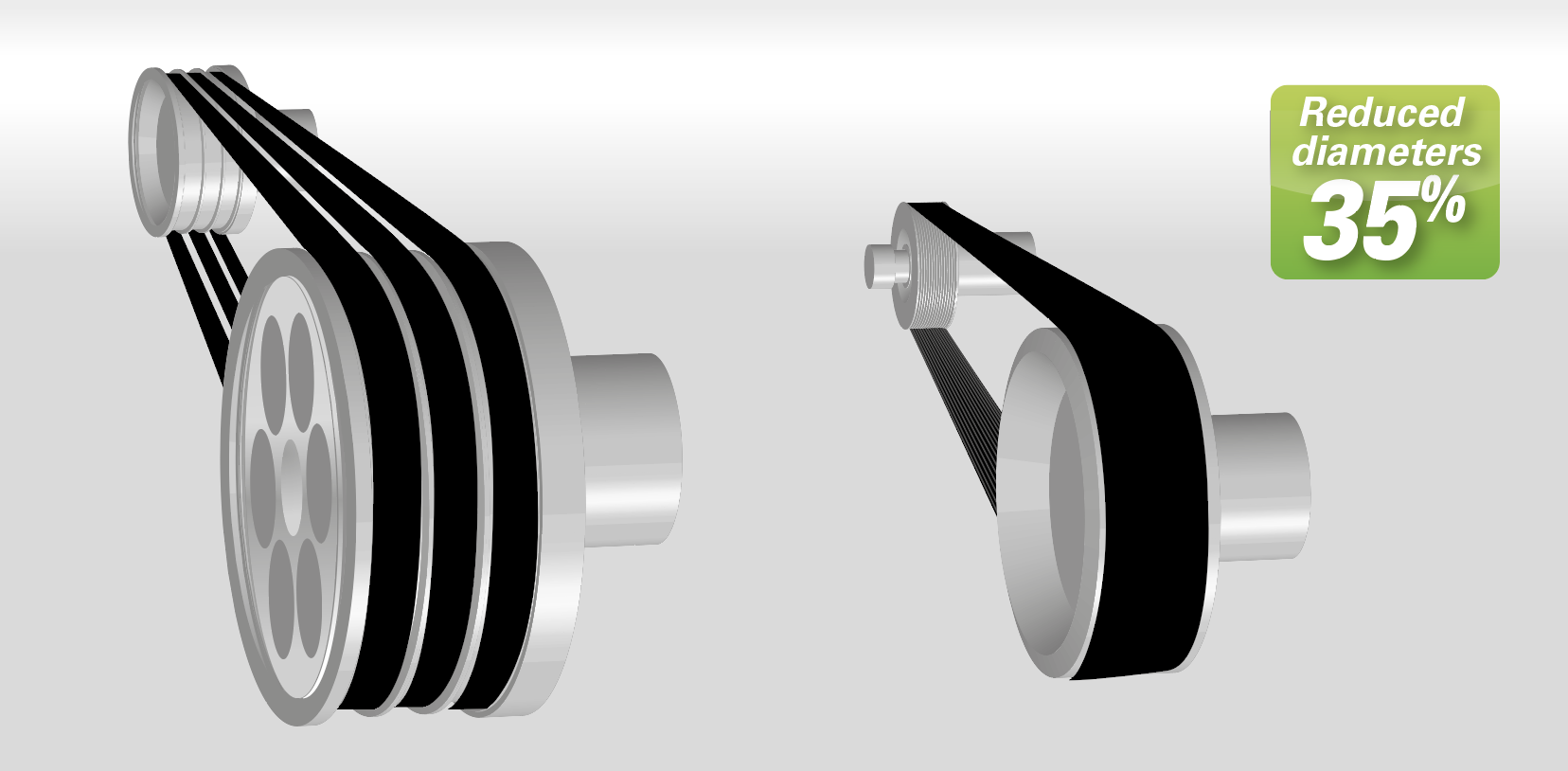

THE COMPACTNESS OF THE TRANSMISSION

- Higher transmission ratio

Ribbed belt 1: 60 vs V belt 1: 20.

Avoids the need for staged pulleys.

- Reduced diameter of the pulleys

The minimum diameters of ribbed profiles are smaller than those of V-Belt profiles.

- Reduced weight of the transmission

No need for a tensioner.

- Reduced belt width for a given geometry and the same power transfer (small ribbed pulley).

Moreover, the Poly V can operate in flexion and counter flexion with the following benefits:

- A single belt can drive several accessories: serpentine belt installation.

- Driving accessories from the back of the belt.

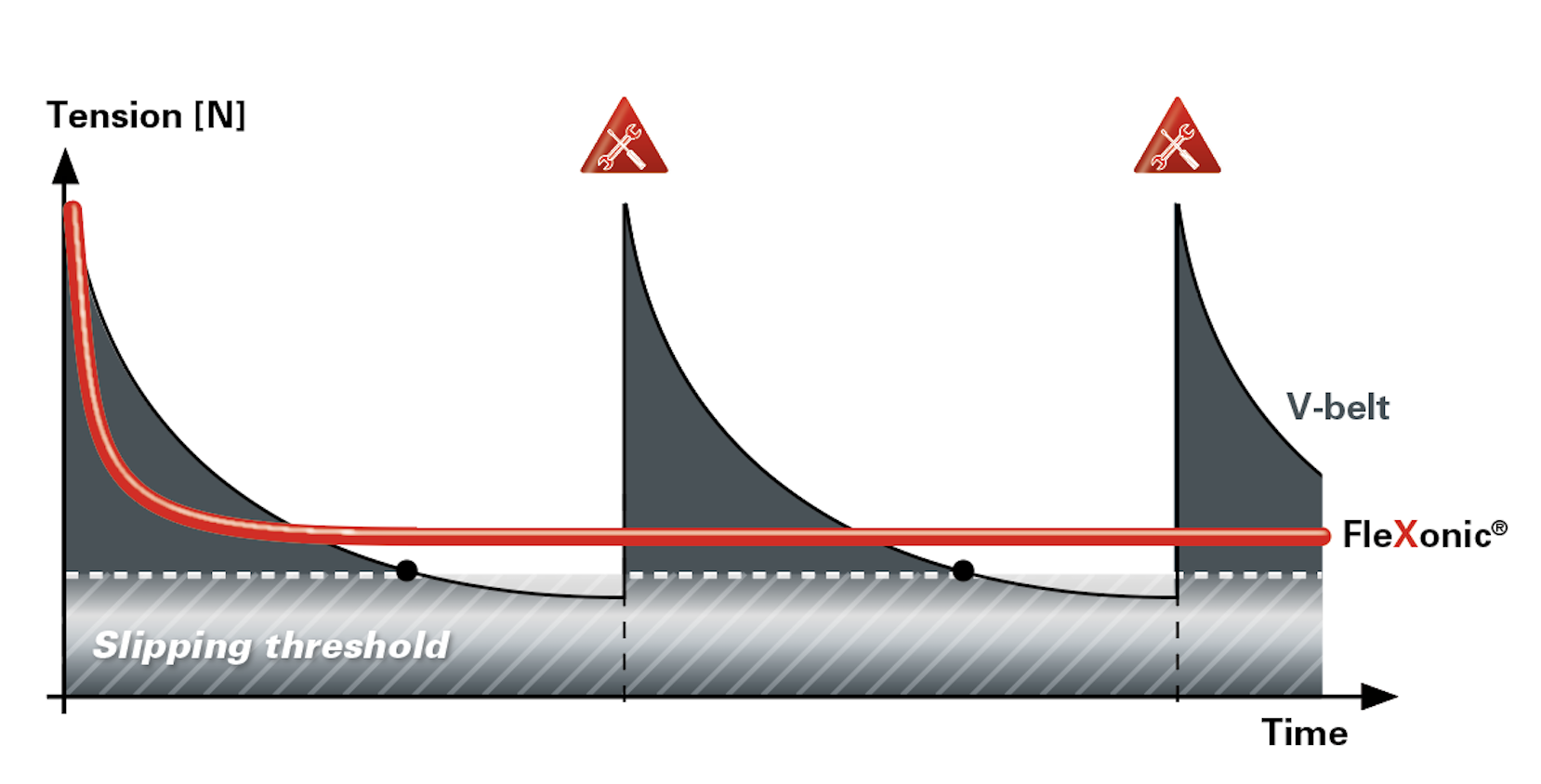

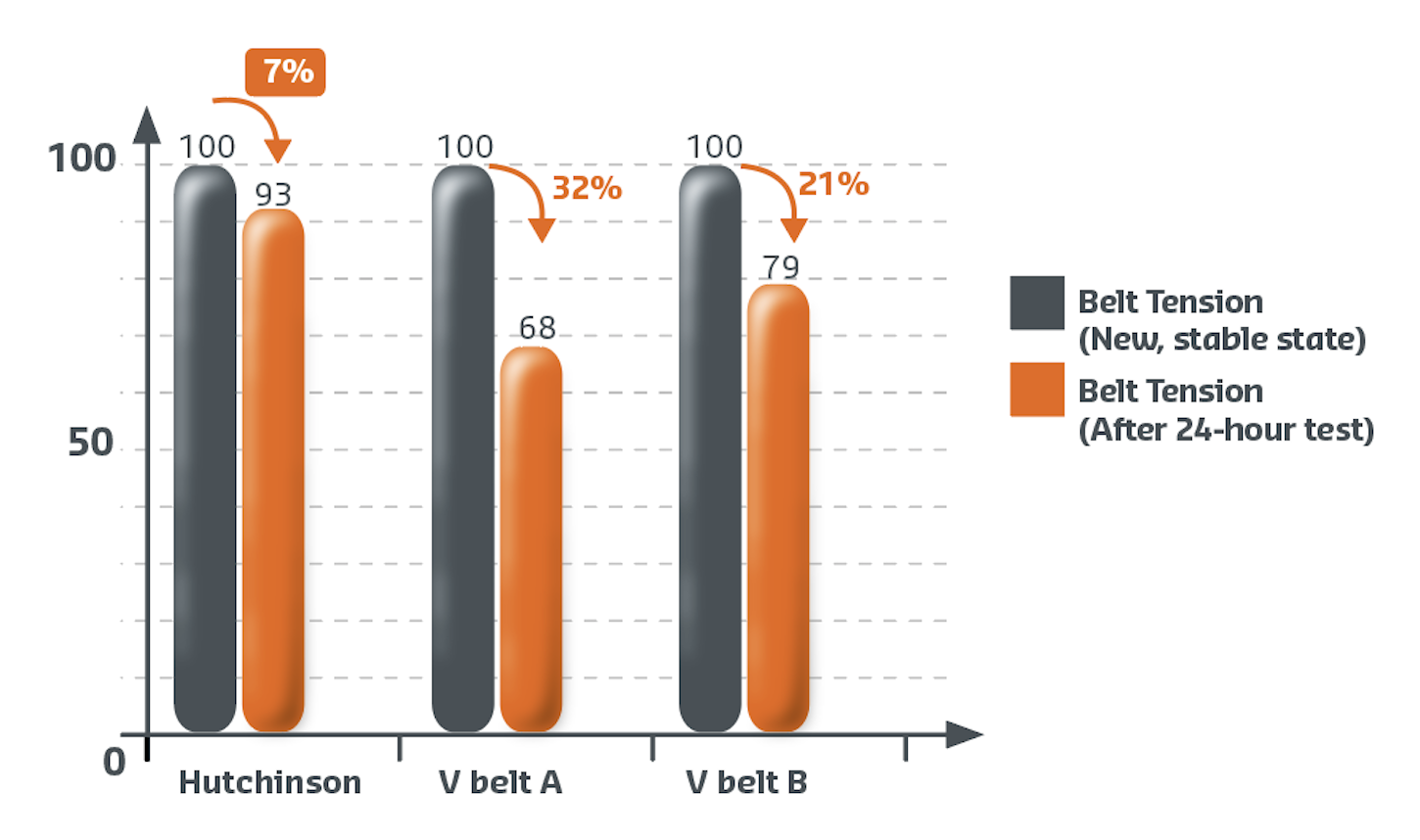

EFFICIENCY

Stable tension: compared to V-Belt no need for matching thanks to the monobloc belt and no differential flapping.

The aging of the belt does not result in any loss of power.

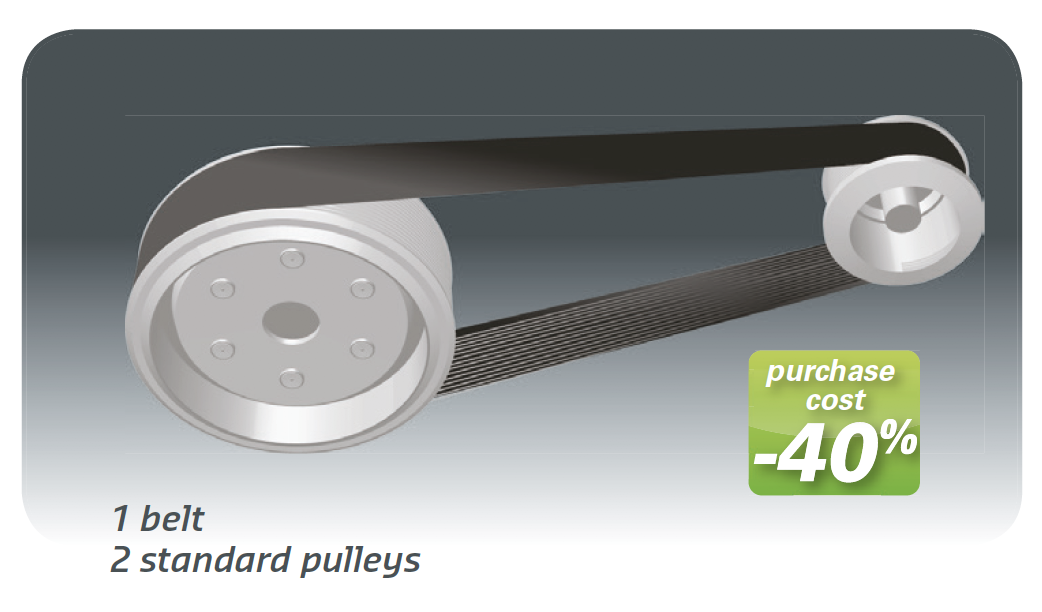

COST REDUCTIONS

PURCHASE:

- Reduced diameter and pulley width.

Compared to V-Belt no need for a tensioner with the Flexonic®. - Lighter transmission

- Reduced belt length

- No need for inertia flywheels in some cases

- Machining of pulleys is facilitating: the Poly V can be used on smooth pulleys (receivers).

MAINTENANCE:

- Rapid set up : 1 PM Poly V can replace up to 25 SPB V belts.

- No need for matching

- Increased lifespan

- No need for re-tensioning and verification operations on the range of elastic belts

- The tension of the Flexonic® can be stabilised after just a few minutes in dynamic performance mode.

Tension will not change throughout the lifetime of the belt.

TIME AND PRODUCTIVITY:

Simpler factory installation of the Flexonic®: time savings and productivity gains.

- Installed on fixed center distance with standard grooved pulleys

- Automatic tensioning

OPERATIONS:

- Reduced energy costs (better transmission effi ciency)

- Increased lifespan of the belt.

STORAGE:

- Standardisation and rationalisation of references.