Poly V Industry

The belt for all applications.

THE POLY V IS A POWER TRANSMISSION BELT

FEATURING MULTIPLE LONGITUDINAL RIBS.

Poly V belt transmits the torque and the power by contact of

the belt rib flanks and the pulley grooves.

The Hutchinson Poly V is a molded belt, its monobloc design guarantees:

- Compactness

- High power transmission

- Operating cost

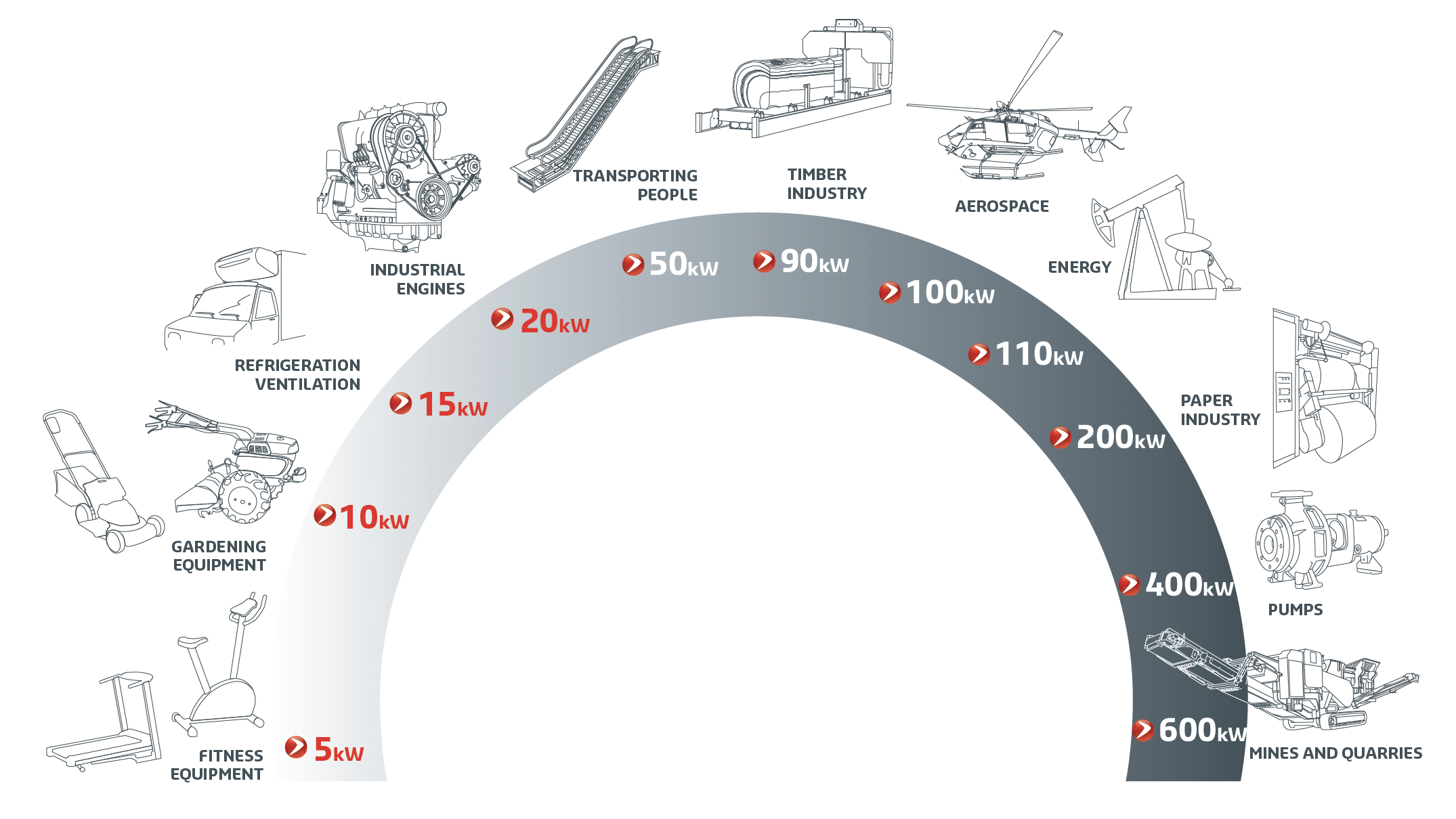

Poly V belt Applications

As a drive belt, the Hutchinson Poly V belt is able to cover a large engine range from light duty to heavy duty machineries (Fitness equipment, gardening, HVAC, Industrial Engines, Energy, Pumps, Mines and Quarries).

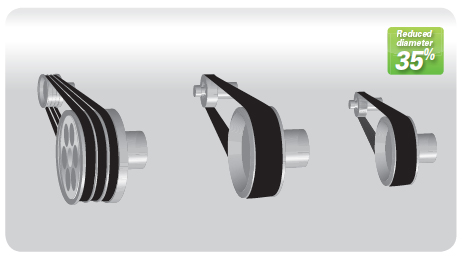

Compactness

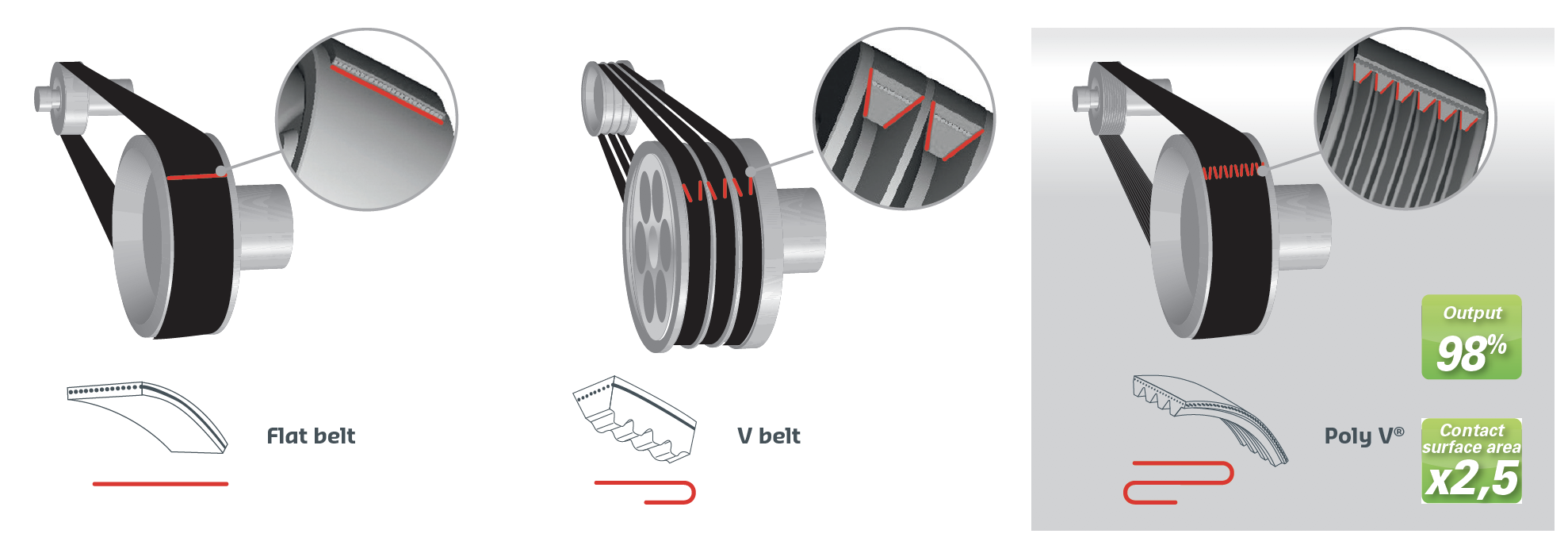

The Poly V has been designed with a larger contact surface area than V belts or flat belts with a single cord.

THE POLY V HAS MULTIPLE APPLICATION BENEFITS:

- Improved transmission ratio is possible (Poly V 1 : 60 vs V belt 1 : 20). Does away with the need for stepped pulleys.

- Reduced diameters (diameters up to 9mm with the H profil compared to 50mm with V belts).

- Reduced belt width for a given geometry and the same power transfer.

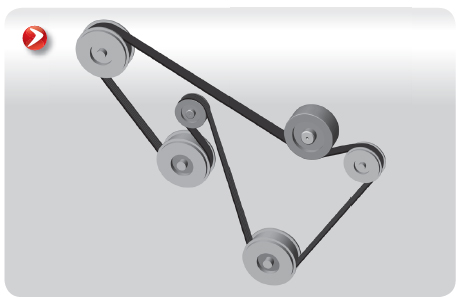

Moreover, the Poly V can operate in flexion and counter flexion with the following benefits:

A single belt can drive several accessories: serpentine belt drive.

- Driving accessories, such as Idlers and drive pulleys from the back of the belt.

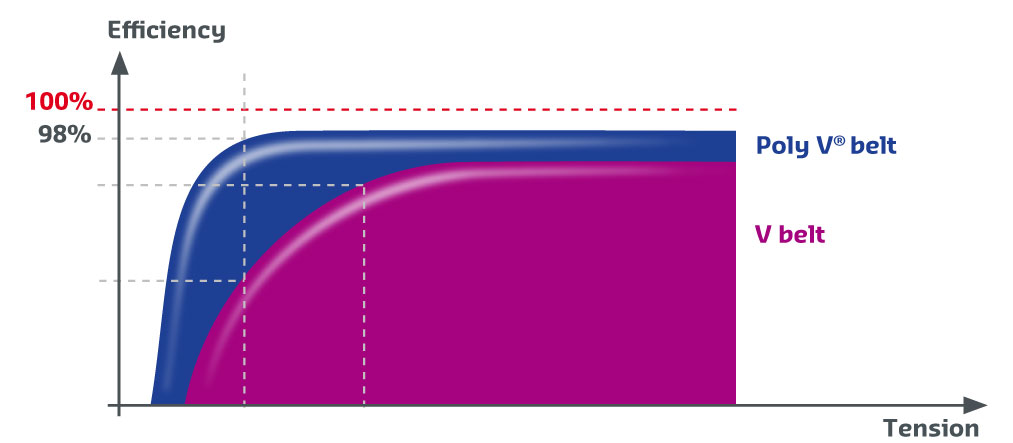

High output:

SMALLER CARBON FOOTPRINT:

Iso-tension and iso-geometry technical tests show that the Poly V can achieve an output several percent higher than Vbelt: over 98%, which can reduce energy consumption and sometime even engine size.

Reduced costs:

BENEFITS:

- Reduced diameter and pulley width.

- Reduced belt length.

- No need for inertia flywheels in some cases.

- Machining of pulleys is facilitated: the Poly V can be used on smooth pulleys (receivers).

MAINTENANCE:

Rapid set up (1 Poly V can replace up to 15 V belts).

- No need for matching.

- Increased lifespan.

OPERATING:

Reduced consumption due to high output.

COMPLEMENTARY CUSTOMER SERVICES

Hutchinson Belt Drive Systems has designed:

- Easy Tension app to measure the frequency or the belt tension

of your Poly V Hutchinson Belt. - Poly V Design mobile app to design a Poly V belt for

an electric engine in all simplicity.

More details in our Poly V belt leaflet.